- #POST PROCESSOR POWERMILL CONFIGURATION MANUAL#

- #POST PROCESSOR POWERMILL CONFIGURATION PRO#

- #POST PROCESSOR POWERMILL CONFIGURATION SOFTWARE#

- #POST PROCESSOR POWERMILL CONFIGURATION CODE#

Stock analysis – Quickly identify material left unmachined using color-coded shading modes. New options to detect and display collisions with stock. Stock simulation – Dynamic ViewMill now provides improved image quality.  Comprehensive tool support – Access a comprehensive suite of tool types, including barrel cutters, and combine with 3- and 5-axis strategies to meet your machining needs. Dynamic machine control in region (PREMIUM, ULTIMATE) – Select multiple regions of your toolpaths, use a virtual CNC machine to dynamically apply alternative tool axis settings. Automatic orientation vectors – Improve the synchronisation between 5-axis simulations and actual NC program output. Interactive collision avoidance – Use interactive tools to help identify and repair toolpath motion that can cause collisions or near misses. Expert 5-axis control (PREMIUM, ULTIMATE) – Make global or localized edits to 5-axis toolpaths for improved machine motion and shorter cycle times. Auto tool tilting (PREMIUM, ULTIMATE) – Simplify the process of creating collision-free 5-axis toolpaths with automatic tool axis tilting. Machine the most challenging parts more safely and efficiently. 5-axis machining (PREMIUM, ULTIMATE) – Go beyond 3+2 with continuous 5-axis machining. Efficient 3+2 programming – Machine difficult-to-reach features with fewer setups, shorter tools, and more aggressive feeds and speeds.

Comprehensive tool support – Access a comprehensive suite of tool types, including barrel cutters, and combine with 3- and 5-axis strategies to meet your machining needs. Dynamic machine control in region (PREMIUM, ULTIMATE) – Select multiple regions of your toolpaths, use a virtual CNC machine to dynamically apply alternative tool axis settings. Automatic orientation vectors – Improve the synchronisation between 5-axis simulations and actual NC program output. Interactive collision avoidance – Use interactive tools to help identify and repair toolpath motion that can cause collisions or near misses. Expert 5-axis control (PREMIUM, ULTIMATE) – Make global or localized edits to 5-axis toolpaths for improved machine motion and shorter cycle times. Auto tool tilting (PREMIUM, ULTIMATE) – Simplify the process of creating collision-free 5-axis toolpaths with automatic tool axis tilting. Machine the most challenging parts more safely and efficiently. 5-axis machining (PREMIUM, ULTIMATE) – Go beyond 3+2 with continuous 5-axis machining. Efficient 3+2 programming – Machine difficult-to-reach features with fewer setups, shorter tools, and more aggressive feeds and speeds. #POST PROCESSOR POWERMILL CONFIGURATION CODE#

Create high-quality NC code regardless of model quality.ĥ-axis programming and multi-axis machining

Every CAD support – Import surfaces, solids, or meshes from mainstream CAD systems. Rib machining (PREMIUM, ULTIMATE) – Produce cutter-friendly toolpaths to mill ribs in molds and dies. Automatically check for collisions and minimise air cutting. 2.5D programming – Interactively create 2D features, toolpaths, and NC code. Make better use of the 3D view, and quickly access commonly used commands. Ribbon interface – Improved interface and user experience. Autodesk Drive (subscription only) – Securely store, preview, and share PowerMill data with project stakeholders. Posts in the cloud (subscription only) – Use a secure, cloud-based platform to manage CNC post-processors. Machining setups – Manage workplanes, stock and clamps when programming parts using multiple operations. Subscribers can share 3D reports with Autodesk Drive. Surface probing ULTIMATE (additional subscriber benefits) – Create probing toolpaths to measure parts with spindle probes. Toolpath optiomisation – Make global or localised edits to your toolpaths without the need for lengthy recalculations. #POST PROCESSOR POWERMILL CONFIGURATION MANUAL#

Improve surface finish, while minimising manual polishing.

Comprehensive finishing – Access a vast library of toolpaths.

Prolong tool life and reduce maintenance costs.

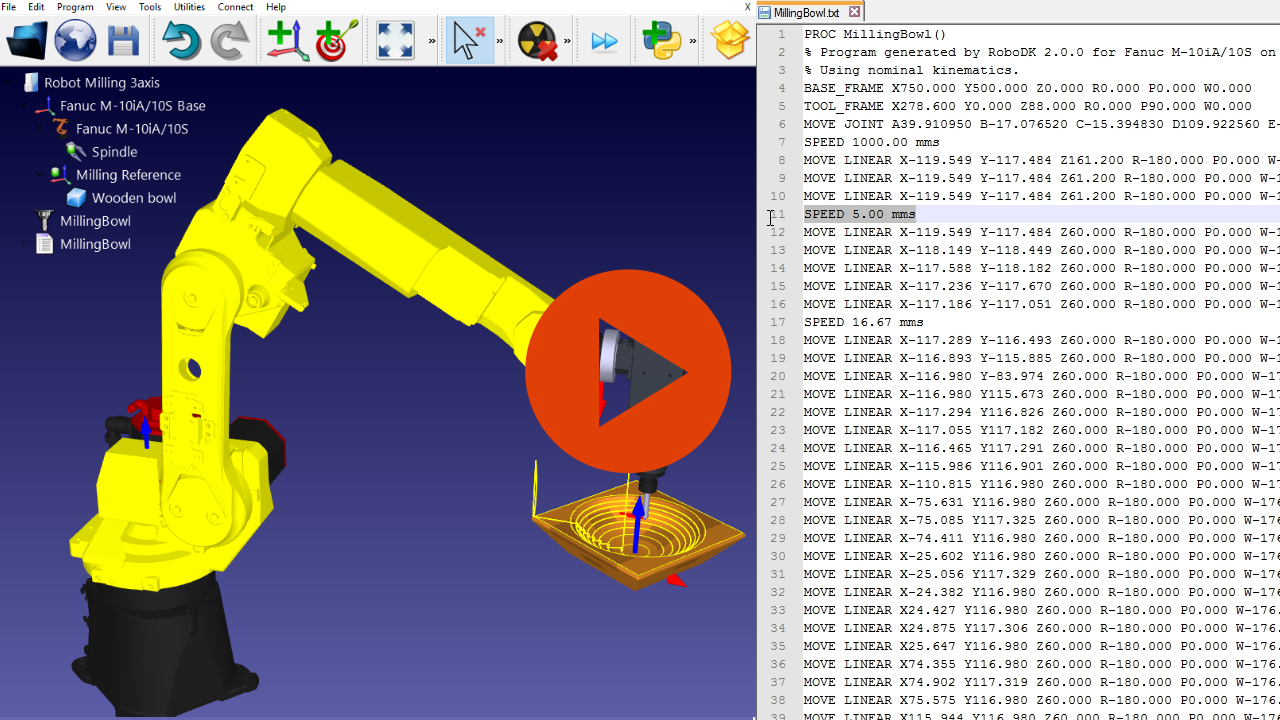

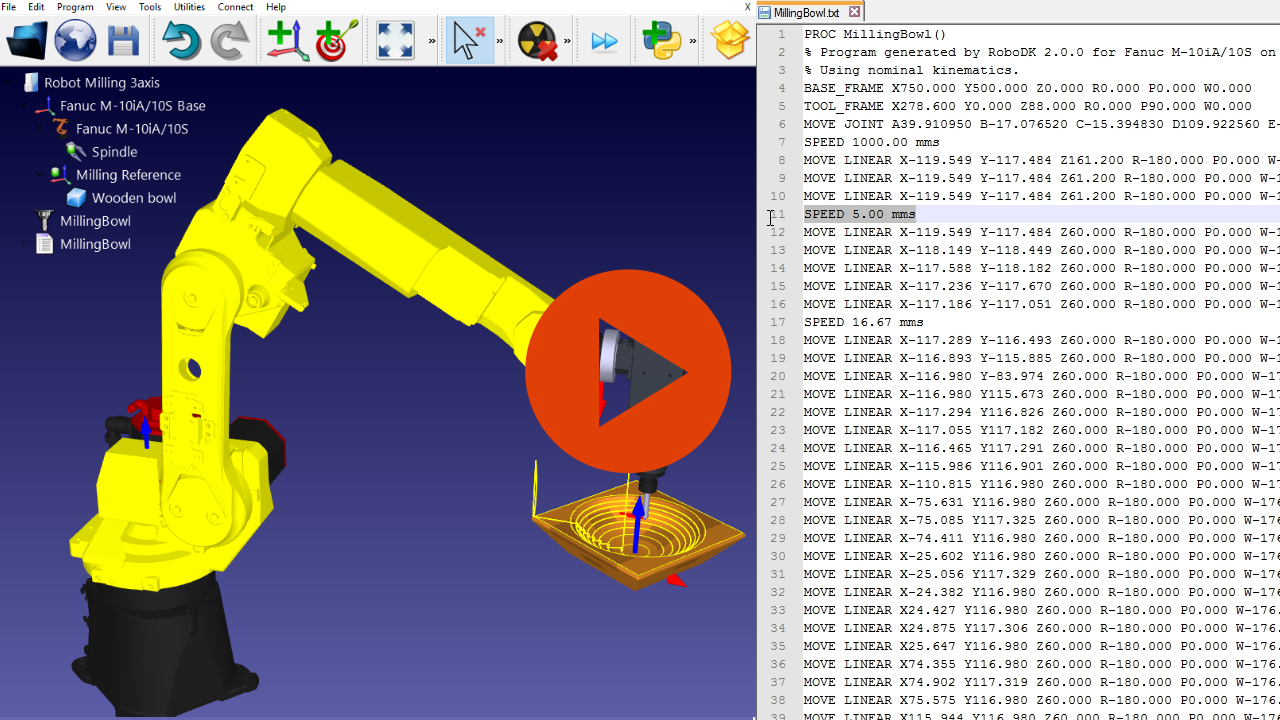

High-speed roughing – Cut parts faster with high-efficiency roughing. Exper performance – Rapid calculation of toolpaths for large or complex parts. Making better use of 3- and 5-axis machineryįeatures in PowerMill® enable easier 5-axis programming, simulation, and verification, so manufacturers can get more from their subtractive, additive, and hybrid machines. Improving the precision and quality of machined parts. Boosting productivity through process automation. Programming extremely large or complex geometry. Reducing the time taken to create efficient NC code. Boost your productivity by embedding your unique manufacturing expertise into automated templates that can be shared across your engineering team. Ultra-efficient algorithms and exceptional levels of customisation and control allow you to create, verify and optimise toolpaths to machine the most challenging parts. #POST PROCESSOR POWERMILL CONFIGURATION PRO#

Start making parts faster with expert CAM performance Whether you’re new to CAM programming or a seasoned pro – PowerMill makes it even easier to machine large or complex parts, where quality, accuracy and efficiency are critical. Use powerful simulation tools to validate and enhance the motion of 5-axis machines. Access a vast library of toolpath strategies and combine with advanced optimisation tools to generate the NC code needed to produce exceptional quality parts.

#POST PROCESSOR POWERMILL CONFIGURATION SOFTWARE#

Autodesk® PowerMill® is expert CAM software for manufacturers of molds, dies and highly complex componentswanting to achieve the maximum quality, control, and efficiency from their CNC machines.

0 kommentar(er)

0 kommentar(er)